USES

CEM260 provides a smooth, leveled, monolithic substrate ready for the application of floor tile, linoleum, sheet vinyl, carpet, wood parquet or other floor coverings without troweling.

CEM260 is a cementitious material that is so fluid that when pumped or poured, it readily flows to form a smooth surface with a resulting dense, non-shrink underlayment surface for normal pedestrian traffic in warehouses, industrial plants, tunnels, apartment floors, or balconies and in areas where free flowing mortar repairs are needed for hard to reach areas.

CEM260 fills small holes, static cracks and depressions as it levels. CEM260 is non-hazardous designed to give excellent bond and a durable surface. In one operation, CEM260 develops high bondability, rapid strength and leveled floors. This cement-based polymer reinforced liquid mix is spread in place from featheredge to one inch /25 mm in one application without aggregate, and to virtually any depth when mixed with aggregate.

Compatibility: CEM260 is compatible with most floors covering adhesives and mastics. CEM260 is applied to dry, primed interior concrete, wood, plywood, steel and most other clean structurally sound floor surfaces.

TECHNICAL

Physical Properties

| Property |

Value * |

Standard |

| Compressive Strength, psi (MPa)* |

1 day |

1470 (10) |

ASTM C109 |

| 7 days |

2460 (29) |

| 28 days |

5590 (38) |

| Flexural Strength, psi (MPa)* |

1day |

560 (3.8) |

ASTM C348 |

| 7 days |

1160 (7.9) |

| 28 days |

1200 (8.2) |

| Setting Time, minute |

Initial |

150 |

ASTM C-191 |

| Final |

190 |

| Working time @ 77°F (25°c), minutes |

30 |

–

|

| Bond strength, Psi (MPa) |

250 (1.7) |

ASTM D-4541 Method A |

*Results obtained when CEM260 is mixed with 50% by weight aggregates 1/8th (3 mm) 3/8th inch (9 mm).

Water requirements: 1.1 Gal per 50 Lb ((4.17 L per 22.68 Kg) bag

Mixed Density: 17.9 Lb /Gal (2.15 Kg/L)

Coverage: one bag CEM260 will cover approximately 40 ft2 (3.5 m2) at approximately 1/8th inch (3 mm) thickness.

APPLICATION

Limitations: Do not mix or apply when temperatures below or expected to fall below 40°F (4°C) within 24 hours. Do not apply CEM260 over very warm surfaces such as radiant heated floors. Do not over water or over mix CEM260. Do not add cement, lime, gypsum, plaster, bonding admixtures, or any other materials except specified aggregates.

CEM260 is not a wearing surface, and it must be protected with a final floor covering or approved coating. Always apply a test area of CEM260 to confirm the suitability of the application and use.

Surface Preparation: surface must be clean of oil, grease, dirt, curing compounds and laitance down to sound concrete. All floors must be solid and have a rigid base.

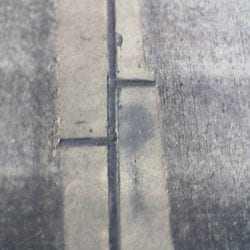

Concrete Surface: Concrete must be fully cured for 28 days. Joints or cracks in movement must be detailed through the CEM260 to prevent cracking. Concrete must be free of laitance or deteriorated concrete, curing or form release agents, and other contaminants.

Surface Priming: surface must be primed before application of CEM260. Apply a thin, continuous coat of EB550 SBR, free of pinholes with a soft bristle push broom. Remove excess EB550 SBR, primer from the surface. If pinholes develop in the first coat, apply a second coat after the first coat has dried. Apply CEM260 within 24 hours of primer application.

Mixing of CEM260: Mix CEM260 in a clean rotary mixer equipped with rubber tipped blades. While the mixer running, add 4.17 liters. of potable water, and then slowly add the 50 Lbs (22.7 kg) bag of CEM260. Mix for approximately 2-3 minutes, and long enough to provide a smooth, lump-free, flowable blend. If foam appears on top of the mixture, CEM260 is over watered. For large surface areas requiring fills greater than 25 mm, add clean, dry, graded and sand free pea-gravel to the mix. Add no more than 25 Lbs (11.25 Kg) of 1/8th – 3/8th (3–9 mm) size per bag of CEM260. Mix the CEM260 first, and add the dry aggregate to the mixed material. Reduce the water required, if the aggregate is damp. Large gravel can reduce material flowability. CEM260 can be mixed in small quantities in a clean container using a slow speed motor and jiffy mixer. Do not mix more than can be used in 10–15 minutes.

Installation: pump or hand pour mixture of CEM260 onto the primed surface, move it into approximate position with an underlayment spreader notched trowel and allow the material to seek its own level. Rolling of the spread mixture with nylon spiked roller will eliminate air bubbles appearing on the surface. Place CEM260 within 10–12 minutes of mixing and keep continuity of pouring without breaks. It will achieve initial set in approximately 20 minutes, and may be walked on in approximately 2–4 hours.

Curing: CEM260 must cure 15–24 hours before the floor covering is installed. Note: For epoxy overlayments systems, allow 7 days cure @ 70°F (21.1°C). During cure, protect the surface from direct sunlight and extreme winds to prevent rapid premature hydration.

Additional Layers: when additional thickness is required, CEM260 may be layered to provide additional depth. The additional layer may be applied directly over the surface as soon as it will support foot traffic. EB550 SBR primer must be used if more than 24 hours passes before the new layer is applied.

Cleaning: Clean mixing and application equipment with water immediately following use.

STORAGE

Store CEM260 in cool dry storage facilities. Do not expose to direct sunlight. The shelf life of CEM260 is minimum 1 year if stored in a cool dry place in its original unopened container.

SAFETY

CEM260 is a cement based, and is recommended that the following ACI practices be followed:

- ACI 304 – for measurement, mixing, transportation and application of concrete.

- ACI 305 – for hot weather application

- ACI 306 – for cold weather application.

- ACI 308 – for curing concrete.

Do not add plasticizer, cement, sand, or accelerator to CEM260. Use only clean water for mixing. Use 3/8th – ½ inch (8-10 mm) pea gravel when grout lifts exceed 3 inches (75 mm).

Prior to application of CEM260 soak surfaces with clean water. At the time of application, the substrate should be damp but free of standing water.

Avoid mixing more grout than can be applied in 15 minutes and avoid application when temperatures are, or will be below 40°F (4°C) in the next 24 hours. On large jobs, rapid and continuous mixing and application are necessary.

Handling Precautions: CEM260 is a non-flammable and non-toxic in nature. Avoid contact with eyes and skin as it may cause irritation due to its alkaline nature. Splashes of CEM260 should be washed off immediately with clean water. Wear necessary gloves and dust mask.

WARRANTY

LIMITED WARRANTY: International Chem-Crete Inc. warrants that, at the time and place we make shipment, our materials will be of good quality and will conform to our published specifications in force on the date of acceptance of the order.

DISCLAIMER: The information contained herein is included for illustrative purposes only and, to the best of our knowledge, is accurate and reliable. International Chem-Crete Inc. is not under any circumstances liable to connection with the use of information. As International Chem-Crete Inc. has no control over the use to which others may put its products, it is recommended that the products be tested to determine the suitability for specific applications and/or our information is valid in particular circumstances. Responsibility remains with the architect or engineer, contractor and owner of the design, application and proper installation of each product. Specifier and user shall determine the suitability of the product for specific application and assume all responsibility in connection therewith. AM210319