USES

CEM210 is a non-shrink cementitious repair mortar with greater flexural and shear bond strengths. The non-shrink quality of CEM210 remains constant throughout the life of the repair patch. The time proven uses of CEM210 assures precise repairs to concrete, bridge decks, airports, runways, ramp and stair repair, truck docks, industrial floor pre-cast and pipe concrete members.

CEM210 is a non-metallic and non-staining and is excellent for use in high humid, wet and cold conditions and therefore is suited for:

- Paper mills.

- Food processing plants.

- Bottling plants.

- Heavy industrial plants.

- Sewage treatment plans, etc.

CEM210 is also good for anchoring bolts, rails, pipes, pre-cast or pre-stress members.

TECHNICAL

Setting Time: ASTM C-191

| Initial setting time |

30 minutes |

| Final setting time |

40 minutes |

Compressive Strength at 25ºC: ASTM C-109

| One day

Psi (MPa) |

1470 (10) |

| 7 days

Psi (MPa) |

7050 (48) |

| 28 days

Psi (MPa) |

8820 (60) |

Flexural Strength at 25ºC: ASTM C-348

| One day

Psi (MPa) |

630 (4.3) |

| 28 days

Psi (MPa) |

1470 (10) |

Mixed Density: 18.3 lb/gal (2.2 kg/L)

APPLICATION

Surface Preparation: clear surfaces contaminated with oil, grease, dirt and laitance down to sound concrete. In high traffic areas, under-cut the patch hole by 2 inches to avoid feather edging. If any steel reinforcement exposed in the area of repairs remove rust, milscale from the steel by thorough abrading to a bright metal.

Apply a zinc rich primer such as Chem-Crete Zinc Rich Primer one full coat all around the steel reinforcement and allow curing before placement of repair mortar.

Saturate the surfaces with water thoroughly. Remove all excess standing water and leave the dampness on the surface. CEM210 repair mortar should only be placed to substrates, which are damp and free from standing water.

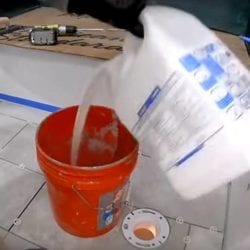

Mixing: Mix CEM210 with a paddle type mortar mixer.

Water consumption: approximately 0.68 gal/50 lb bag (2.6 L)

Place ¾ quantity of the measured water into the mixing container. Add slowly CEM210 while mixing. Add the remaining quantities of water and mix until smooth, putty like consistency is achieved.

Mixing Time: approximately one-two minutes. Avoid mixing more CEM210 more than can be used in 20 minutes.

For deeper patches over 1.5 in, add 22 lb of 6-8 mm pea gravel (cleaned and washed) per 55lb bag of CEM210.

Note: ambient and water temperatures affect setting time. Higher temperature results in shorter setting time.

- Initial set time @ 25°C is 35 minutes.

Priming: generally, CEM210 can be placed on dampen concrete surface straight away. Use of Chem Bond CCC550 or EB550 SBR will improve adhesion monolithic bond.

Placing: immediately upon mixing of CEM210, place the mortar firmly into the damp area and form to final surface configuration in one application, working from edge to eliminate air voids.

Smoothen the surfaces to uneven leveled finished lay using steel trowels, plastic or wooden floats. Upon completion of the surface finish, do not over work.

Curing: immediately after placement, keeps wet and protect surfaces from rapid moisture loss. Protect exposed areas from excessive heat and cold. Cover surfaces with wet burlap and keep damp for minimum 24 hours.

Cleaning: clean all tools and equipment from CEM210 with clean water before the product reaches initial setting. Cured material may only be removed by mechanical means. Tools and equipment contaminated with Zinc Rich Epoxy Primer can be cleaned using blended solvents.

STORAGE

Store CEM210 in cool dry storage facilities. Do not expose to direct sunlight. The shelf life of CEM210 is minimum 1 year if stored in a cool dry place in its original unopened container.

WARRANTY

LIMITED WARRANTY: International Chem-Crete Inc. warrants that, at the time and place we make shipment, our materials will be of good quality and will conform to our published specifications in force on the date of acceptance of the order.

DISCLAIMER: The information contained herein is included for illustrative purposes only and, t the best of our knowledge, is accurate and reliable. International Chem-Crete Inc. is not under any circumstances liable to connection with the use of information. As International Chem-Crete Inc. has no control over the use to which others may put its products, it is recommended that the products be tested to determine the suitability for specific applications and/or our information is valid in particular circumstances. Responsibility remains with the architect or engineer, contractor and owner of the design, application and proper installation of each product. Specifier and user shall determine the suitability of the product for specific application and assume all responsibility in connection therewith. AM200319.