USES

CEM220 mortar is designed for the durable repairs and re-profiling of in-situ and pre-cast concrete in civil engineering structures such as:

- Facades, columns and beams

- Bridges, towers and tunnels

- Parking ramps, overpasses and pass throughs

CEM220 can be used for filling cavities, repairs to spalled concrete, repairs to edges and re-aligning of walls prior to tiling and renovating existing commercial and residential structures to correct uneven structural irregularities.

CEM220 is excellent for re-profiling swimming pool walls prior to tiling, repairs to cold joints and repairs in water tanks and reservoirs. It can also be applied at reduced thickness and can be modified to meet tolerances at stairwells and elevators.

CEM220 prevents damages from mechanical impact and abrasion, environmental and freeze-thaw deterioration and chemical destruction from acids, caustic solutions and other chemical contaminants.

ADVANTAGES

- Suitable for interior and exterior applications.

- Thixotropic and non-sag permits use on vertical and overhead applications.

- Non-shrink with lifetime bonding qualities.

- Ready-to-use requires addition of water only.

- Excellent workability.

Non-toxic and can be used in potable water tanks

PACKAGING

Product

|

Packaging |

| CEM220* |

50 Lb (22.68 kg) Bag |

* Product as Supplied as Cement Grey powder and requires only addition of water.

TECHNICAL

| Property |

Value * |

Standard |

| Compressive Strength,

psi (MPa) |

1 day |

(2226) 15.35 |

ASTM C109 |

| 7 days |

(6203) 42.77 |

| 28 days |

(7893) 54.42 |

| Flexural Strength,

psi (MPa) |

1day |

595 (4.1) |

ASTM C348 |

| 7 days |

1146 (7.9) |

| 28 days |

1523 (10.5) |

| Setting Time**, minute |

Initial |

200 |

ASTM C191 |

| Final |

240 |

| Pot Life**, minute |

35 |

– |

| Density – set mortar,

Lb/Gal (Kg/Liter) |

17.53 (2.10) |

– |

| Chloride Content |

<0.01% |

BS 1881 124 – 83 |

| Adhesion Strength*** |

Concrete Failure |

ASTM D4541 -Method A |

* Average

** Test at 75°F (25°C)

*** Test with EB550 SBR Primer (7days curing)

Note: Above technical data is based on water ratio of 1.078 gal (4.082 liters) per 55 Lb (22.68 kg) bag.

APPLICATION

Limitations: surface and application temperature should be more than 7°C. Apply only to thoroughly clean, sound substrate.

Surface should be saturated water thoroughly. After placing, protect from direct heat and sun. Use mechanical mixer to avoid lumps. Avoid application in rain or contaminated surface. Do not add cement, sand or accelerator.

Water requirement: 1.078 Gallon (4.082 Liter) of water is required for the 50 Lb (22.68 Kg) Bag of CEM220.

Coverage: 55 Lb (22.68 Kg) Bag of CEM220 covers approximately 11.8 ft² @ 0.5 inch thickness (1 m2 @ 14 mm thickness).

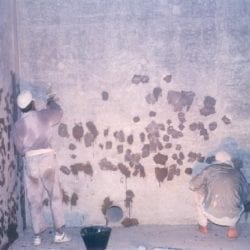

Surface Preparation: al surfaces to receive CEM 220 must be clean and free from all dust, paint, sealers, curing compounds or any other anti adherents. Chip-open the loose concrete until reaching sound base. Avoid featheredges by cutting the edges to a straight cut. Clean the substrate. Substrates contaminated with grease, oil or dirt should be cleaned and treated with CONCLEAN CCC060.

Saturate the substrate with clean water prior to placement.

Mixing: CEM220 may be mixed either by hand or by mechanical mixer. In case of hand mixing do not mix quantities greater than 10 kg at one time. For mechanical mixing, slow speed mini mixer (approximately 400 rpm) or drill fitted with paddle can be utilized.

Pour approximately ¾ of the measured water needed into the mixer then add CEM220 slowly while mixing. After 3-4 minutes add the remaining water and mix until the mortar has the required lump free consistency.

Priming: Apply one coat of CHEM-CRETE EB 550 SBR to the area to be patched immediately prior to placing the CEM220 mortar.

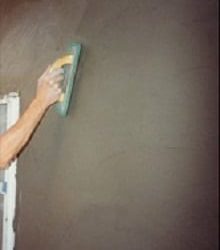

Application: CEM220 mortar may be applied by trowel or spatula. Use the mixed mortar without delay. Firmly place CEM220 mortar into the damp primed area and form to a final configuration working from edge to eliminate air voids.

Thickness: Application thickness on overhead and vertical in one layer is approximately ¾ inch (20 mm). A thickness of 2 ¼ to 2 ¾ inches (57 to 70 mm) can be achieved in multi-layer application.

For repairs that require multi-layer applications always ensure that the preceding layer is stable but not fully set before applying a final finish layer.

Curing: Protect exposed surfaces from excessive heat and cold. Cover surfaces with wet burlap and keep damp for 24 hour at least immediately after initial set at the working temperature.

Cleaning: clean application tools and mixing equipment with water immediately following use.

STORAGE

Store CEM220 in cool dry storage facilities. Do not expose to direct sunlight. The shelf life of CEM220 is minimum 1 year if stored in a cool dry place in its original unopened container.

SAFETY

CEM220 is non-flammable and non-toxic in nature. Avoid contact with eyes and skin as it may cause irritation due to its alkaline nature. Splashes of CEM220 should be washed off immediately with clean water. Wear necessary gloves and dust mask.

WARRANTY

LIMITED WARRANTY: International Chem-Crete Inc. warrants that, at the time and place we make shipment, our materials will be of good quality and will conform to our published specifications in force on the date of acceptance of the order.

DISCLAIMER: The information contained herein is included for illustrative purposes only and, to the best of our knowledge, is accurate and reliable. International Chem-Crete Inc. is not under any circumstances liable to connection with the use of information. As International Chem-Crete Inc. has no control over the use to which others may put its products, it is recommended that the products be tested to determine the suitability for specific applications and/or our information is valid in particular circumstances. Responsibility remains with the architect or engineer, contractor and owner of the design, application and proper installation of each product. Specifier and user shall determine the suitability of the product for specific application and assume all responsibility in connection therewith. AM200319.