USES

CHEM-REPAIR 510 is used extensively in the following applications:

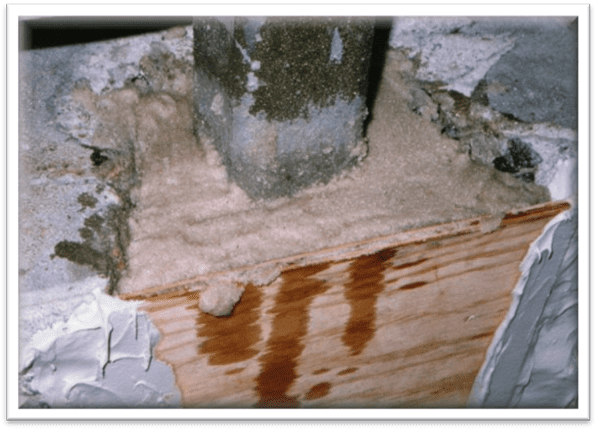

- Repair of concrete structures deteriorated by chemical attack from seawater, salt, exhaust gases, sewage, etc.

- Bridge decks and underpasses.

- Repair of concrete exposed to high static and dynamic load such as bridges, piers, canals, pipelines, basins, etc.

- Repair of frost damaged and spalled concrete.

- Leveling of concrete surfaces.

- Repair in areas of limited shutdown time.

PACKAGING

| Product |

Packaging |

| CHEM-REPAIR 510 |

33 LB (15 KG) KIT*

Part A (Resin): 1.73 Lb (0.78 Kg) / Quart Can

Part B (Hardener): 1.42 Lb (0.64 Kg) / Quart Can

Part C (Graded Filler): 29.86 Lb / 5 Gallon Pail |

*Part A, Part B, and Part C are all packaged together inside 5 Gallon Steel Pail, this provides convenient and easy to use kit.

TECHNICAL

Technical Data for Unmixed Parts

| Property @ 25°C (77°F) |

Resin – Part A |

Hardener – Part B |

Test Method |

| Solids |

100 % |

100 % |

– |

| Color |

Clear |

Grey |

– |

| Density, Lb/Gal (Kg/L) |

9.66 (1.16) |

< 8.04 (0.96) |

ASTM D-1475 |

| Mixing Ratio A : B |

≈1 : 1 By Volume

|

– |

| Shelf Life |

2 years |

2 years |

– |

Technical Data for Mixed Parts

| Property (Mixed A & B) |

Value @ 25°C (77°C) |

Test Method |

| Mixed Density, Lb/Gal (Kg/L) |

16.2 (1.95) |

ASTM D-1475 |

| Gel Time @ 60 grams, minute |

100 |

ASTM D-2471 |

| Pot Life @ 33 Lb (15 Kg), minute |

70 |

– |

| Shore Hardness @ 3 Days, D |

80 |

ASTM D-2240 |

| Compressive Strength, Psi (MPa) |

1 Day |

9166 (63.2) |

ASTM D-579 |

| 3 Days |

10240 (70.6) |

| 7 Days |

10602 (73.1) |

| Bond Strength To Concrete, Psi (MPa) |

Concrete Failure |

ASTM D-4541 Method C |

| Flexural strength @ 7 Days, Psi (MPa) |

3162 (21.8) |

ASTM C-348 |

| Final Cure, day |

7 |

– |

Compatibility: CHEM-PRIME 510 provides permanent adhesion to clean and sound substrates such as concrete, cementitious systems, timber, granolithic screeds, masonry pavings, mild steel, etc.

APPLICATION

Limitations: application at ambient temperature below approximately 41F (5°C) is not recommended. Exposure to temperatures exceeding 149°F (65°C) for prolonged periods is not recommended.

Consumption: approximately 2 kg of CHEM-REPAIR 510 per 1 m2 at 1 mm thickness (3.69 Lbs of CHEM-REPAIR 510 per 1 yard2 at 40 mils thickness).

Surface Preparation: concrete or cementitious substrates should be at least 28 days old and moisture content of substrate should be less than 5%.

All laitance and loose materials must be removed from the concrete surfaces. If the concrete is strong, crack-free and sound with light laitance, surface preparation may be achieved by acid etching followed by thorough water washing using high pressure water jetting ensuring all traces of acids are removed prior to application of the repair screed.

Areas or deeply penetrating contaminations by oil, greases and fats should be flame cleaned by hot compressed air or thoroughly washed by good industrial detergent. The cleanly washed substrate is then allowed to dry completely.

Cracked or damaged concrete or heavy laitance should be removed and prepared by grit blasting, scrabbling or mechanical grinding until a solid surface is reached showing exposed aggregate.

Any corroded reinforcement should be exposed at least 10 mm around the reinforcement and shot blasted to Swedish standard SA 2 ½ (bright metal).

Avoid featheredges in the concrete. Repair areas by saw cutting to a minimum depth of 5 mm. Remove all deleterious concrete until achieving a solid base. Blow out all the dust from the area of repair.

Mixing and Application: CHEM-PRIME 510 must be used to insure bonding. Trowel the mortar into a wet or tacky primer. Mechanical mixing of the epoxy components and silica sands is the most efficient and effective method. Mix part A and part B together then add the silica sand component while mixing.

Cleaning: remove uncured CHEM-REPAIR 510 from tools and equipment with suitable solvents such as Xylene, Toluene or CHEM-CRETE BLENDED SOLVENT immediately after use. Cured material may only be removed mechanically.

STORAGE

The product can be stored for minimum of twelve months at temperature from 41°F to 95°F (5°C to 35°C) in the unopened original packaging. Protect from direct sunlight.

SAFETY

After hardening thoroughly, CHEM-REPAIR 510 is physiologically harmless. Keep the resin and hardener away from the eyes mouth and skin. Do not breathe in the vapors. The uncured mixture can cause irritation of the skin. For best protection, wear rubber or plastic gloves. In case of contamination, wipe away resin or hardener immediately from the skin using paper towels and then wash with soap and water or hand cleaning detergent. Empty resin and hardener cans must be disposed according to local city code or regulations. Under no circumstances empty cans should be used to store food or drink even if they have been thoroughly cleaned. Follow all cautionary direction as printed on container’s labels.

WARRANTY

LIMITED WARRANTY: International Chem-Crete Inc. warrants that, at the time and place we make shipment, our materials will be of good quality and will conform to our published specifications in force on the date of acceptance of the order.

DISCLAIMER: The information contained herein is included for illustrative purposes only and, to the best of our knowledge, is accurate and reliable. International Chem-Crete Inc. is not under any circumstances liable to connection with the use of information. As International Chem-Crete Inc. has no control over the use to which others may put its products, it is recommended that the products be tested to determine the suitability for specific applications and/or our information is valid in particular circumstances. Responsibility remains with the architect or engineer, contractor and owner of the design, application and proper installation of each product. Specifier and user shall determine the suitability of the product for specific application and assume all responsibility in connection therewith. AM22319.