USES

CHEM-INJECT 1OO is used for

- Injection of live cracks subjected to limited movements.

- Filling of dry and damp cracks in concrete and stone or masonry.

- Durable, impermeable sealing of expansion joints, cold joints and construction joints where flexible sealing requirements are in demand.

- Elastic sealing and filling of fine cracks, honeycombs, voids, etc.

USES: Chem-Inject 100 is extensively used to inject in the following fields:

Dynamic cracks in:

- Columns, beams, floors and piers.

- Bridge decks, underpasses and tunnels.

- Basements and abutments.

- Waste water treatment plants.

- Water reservoirs, tanks and swimming pools.

Other uses:

- Sealing of expansion joints, construction joints and cold joints.

ADVANTAGES

Ready to use work pack ensuring correct mixing.

- Low viscosity that permits reliable penetration into the minute porosity of the concrete.

- Good adhesion to dry and damp concrete.

- Excellent flexibility.

- Impermeable to water and withstands permanent water pressure.

- Shrink-free and solvent free.

- Suitable for injection with one-component injection pumps.

PACKAGING

| Product |

Packaging |

| CHEM-INJECT 100 |

2 Gallon (7.57 Liters) Unit

Part A: 1 Gal Can, Part B: 1 Gal Can |

| 10 Gallon (37.85 Liters) Unit

Part A: One 5 Gal Pail, Part B: One 5 Gal Pail |

Part ‘A’ = Clear liquid resin

Part ‘B’ = Clear liquid hardener

TECHNICAL

Technical Data for Unmixed Parts

| Property @25°C (77°F) |

Resin – Part A

|

Hardener – Part B

|

Test – Method

|

| Solids |

100% |

100% |

–

|

| Color |

Clear |

Clear |

–

|

| Density, lb/gal (kg/L) |

9.0 (1.09) |

8.1 (0.97) |

ASTM D1475 |

| Shelf life |

2 years |

2 years |

–

|

| Mix ratio (A:B) |

1:1 (by volume) |

–

|

Technical Data for Mixed Parts

| Property (Mixed A & B) |

Value @ 25°C (77°C) |

Test Method |

| Mixed Density, Lb/gal (Kg/L) |

8.66 (1.04) |

ASTM D1475 |

| Viscosity |

480 cps |

Brookfield |

| Gel time (60g), minute |

75 min |

ASTM D-2471 |

| Shore hardness, A |

65-A |

ASTM D-2240 |

| Tensile strength |

7 N/mm2 |

ASTM D-638 |

| Bond strength @ (48 hrs) |

Concrete failure |

ASTM C-882 |

| Elongation, % |

100 |

ASTM D-638 |

| Water absorption %, (24 hrs) |

0.13 % |

ASTM D-570 |

| Final Cure |

7 Days |

–

|

Compatibility: CHEM-INJECT 100 can be injected into concrete, natural stone, masonry, brick and mineral based plasters of all kinds.

APPLICATION

Consumption: 1 kg mixture of CHEM-INJECT 100 can seal approximately 3 linear meter length of crack with 1 mm crack width and 30 cm concrete thickness (crack depth).

Limitations:

| Minimum substrate temperature |

+ 5 °C |

| Minimum temperature of product for mixing |

+ 15 °C |

| Minimum temperature for curing |

+ 5 °C |

Injection of Chem-Inject 100:

Pre-treatment of Substrate:

The substrate must be sound, clean and free from oil and grease. All loose material and laitance along the crack length should be removed with suitable hand tools such as needle guns, wire brushes or angle grinders.

Injection Packers: Two types of injection packers are available, adhesive (surfaces) packers and drilled packers. The selection of the packer type depends on the thickness of the substrate and the nature of the crack (width, depth, shape and propagation). The crack nature will affect the operating pressure used in the injection process. Normally, drilled packers can be operated at higher pressures than adhesive packers.

Setting Injection Ports: The crack nature and substrate will affect the distance between the packers. Generally, packers should be installed at distances between 20-50 cm along the crack length.

Adhesive Packers are recommended mainly in dry or slight damp concrete. Adhesive packers are recommended for wide or surface cracks and clear in nature cracks and when the substrate thickness is small. Injection of minor cracks is possible but subject to site inspection and demonstrations and will be dependent on a slow operating injecting pressure.

Drilled Packers can be recommended for both dry and wet concrete and for all sizes and nature of cracks. Drilled packers can be installed along the crack length or alternating on both size of the crack length. When drilling on the side of the crack at 45° inclination a special care must be taken in insuring that drilled holes crosses the crack section.

Sealing of Cracks: After the completion of surface preparation and drilling the injection ports, clean the surface and injection ports adequately by dry and oil free compressed air. Adhesive packers should be fixed using Chem-Versatile crack sealing compound. Drilled packers are installed and tightened in the drilled ports. Seal the crack length completely by applying a minimum of 50 mm band of Chem-Versatile crack sealing compound. Allow the applied CHEM-VERSATILE to cure for minimum 8-12 hours before commencing the injection process.

Mixing: Find a suitable dry clean container for mixing. Pour both component “A” and “B” completely and mix thoroughly using a slow speed electric drill with mixing paddle (max. 300 rpm). Mix from side to side and top to bottom until a fully homogeneous mixture is obtained.

Mixing Time: Approximately 3-4 minutes.

Pot Life: The prepared mix should be used up immediately before the pot life of the products

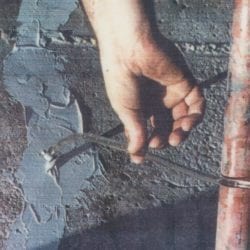

Injection: Pour the mixture of CHEM-INJECT 100 into a suitable injection pump. For a wall, commence the injection at one side of the crack then progress to the adjacent packer, until the whole crack length is completely injected. Due to the low viscosity and long pot life of CHEM-INJECT 100 and with the adequate injection pressure, the injection resin will flow, fill and seal all voids and subsiding cracks.

Curing: Allow Chem-Inject 100 to cure for at least 48 hours. Remove the adhesive packers with a hammer or cut-off the drilled packers using angle grinder.

The cured CHEM-VERSATILE can be removed from the concrete surfaces using angle grinder with concrete grinding disc or by flame scaling method with blow torch and scraping out the burnt Chem-Versatile.

Cleaning: tools and equipment must be cleaned immediately after use, with Blended Solvents, Xylene, Toluene, etc.

Caution: Solvents are flammable also they may affect the seals of injection pumps if exposed to solvent for longer period.

STORAGE

The product can be stored in a dry, cool place for twelve months in unopened original packaging. Do not store below +15 °C or in direct sunlight.

SAFETY

After hardening thoroughly, CHEM-INJECT 100 is physiologically harmless.

Keep the resin and hardener away from the eyes mouth and skin. Do not breathe in the vapors. The uncured mixture can cause irritation of the skin. For best protection, wear rubber or plastic gloves. In case of contamination, wipe away resin or hardener immediately from the skin using paper towels and then wash with soap and water or hand cleaning detergent.

Empty resin and hardener cans must be destroyed. Under no circumstances use them to store food or drink even if they have been thoroughly cleaned.

WARRANTY

LIMITED WARRANTY: International Chem-Crete Inc. warrants that, at the time and place we make shipment, our materials will be of good quality and will conform to our published specifications in force on the date of acceptance of the order.

DISCLAIMER: The information contained herein is included for illustrative purposes only and, to the best of our knowledge, is accurate and reliable. International Chem-Crete Inc. is not under any circumstances liable to connection with the use of information. As International Chem-Crete Inc. has no control over the use to which others may put its products, it is recommended that the products be tested to determine the suitability for specific applications and/or our information is valid in particular circumstances. Responsibility remains with the architect or engineer, contractor and owner of the design, application and proper installation of each product. Specifier and user shall determine the suitability of the product for specific application and assume all responsibility in connection therewith. AM22319